-

ManuThe baler machine works very well.

ManuThe baler machine works very well. -

AnkitYour baler is very good and works well.Scrap metal bales are great.

AnkitYour baler is very good and works well.Scrap metal bales are great.

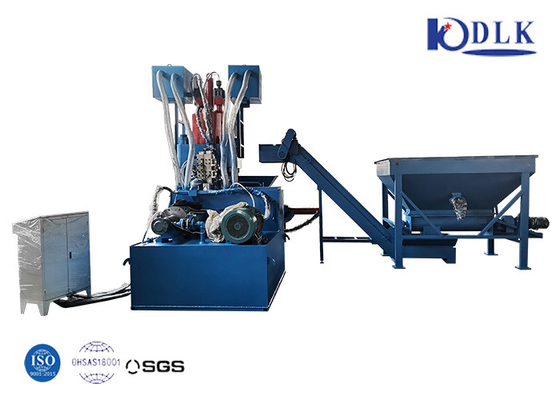

Hydraulic Metal Briquetting Machine Vertical Press For Copper Chips

| Machine Type | Copper Chips Briquetting Machine | Hydraulic System Working Pressure | <29MPa |

|---|---|---|---|

| Block Size | Φ200x~100mm | Nominal Force | 630 Tons |

| Power Specifications | 380V/3P 50Hz | Power | 60kW |

| Handling Material | Crushed Material (iron, Steel, Aluminum, Copper) | Color | Gray & Green (Customized) |

| Warranty | 1 Year | ||

| Highlight | Chips Briquetting Machine,Hydraulic Metal Briquetting Machine Vertical,Metal Copper Briquetting Machine |

||

Vertical Hydraulic Press For Metal Copper Chips Briquetting Machine

Product Description

We Dalongkai mainly produce scrap metal balers and scrap metal shears. This machine is Y83 series scrap metal briquetting machine. Without adding any additives, in addition to cast iron scraps and iron ore powder raw materials, various granular and powdered cast iron, aluminum, copper, magnesium, titanium, molybdenum, etc. can also be pressed into high-density briquette, so as to facilitate the Transportation and casting. Directly put into the furnace for smelting not only ensures that the original material remains unchanged, but also the recovery loss of the furnace does not exceed 10%. The molding also ensures that the original material remains unchanged.

Technical Parameters

| NO. | Parameter name and content | |

| 1 | Model | Y83-630 |

| 2 | Master Cylinder Pressure | 630 Ton |

| 3 | Hydraulic System Working Pressure | <29MPa |

| 4 | Block Size | Φ200x~100mm |

| 5 | Block Density (Steel) | ≤3500kg/m³ |

| 6 | Power Specifications | 380V/3P 50Hz |

| 7 | Power | 60 KW |

The parameters in the above table are for reference only.

![]()

Components of the briquetting machine:

1. Main machine: It is composed of frame, main hydraulic cylinder, pushing hydraulic cylinder, bottom hydraulic cylinder, supporting mold frame, mold, pressure head, etc.

2. Hydraulic station: It is composed of motor, hydraulic pump, pump protection device, professional control valve block and piping system for connecting the briquetting machine.

3. Console: composed of electrical system and plc control system.

![]()

![]()

Company Profile

Certifications

![]()

FAQ

Q1:Are you a manufacturer, trading company or a third party?

A:We are a professional manufacturer of large and medium-sized hydraulic machinery and equipment in China, and also one of the production bases of metal hydraulic baler and metal shearing machine.

Q2:What is your minimum order quantity, can you send me samples?

A:Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, however,we can send you catalog.

Q3: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Our factory address: 29# Panlongshan Road,Jiangyin city,Jiangsu province,214429, P.R China

Our factory is near Shanghai Pudong Airport.We can pick you up in the airport.

Hotel booking service is available .

Q4:As the shipping period will take long time, how can you make sure the machine won’t be broken?

A:Our machine is film wrapped, to make sure the machine can be delivered to our customer smoothly, we will use the steel wire to fix the machine with the container.

Q5:How to Install ?

A:a.For vertical baler machines, no need to install. This kind of machine is exported by complete unit.

b.For horizontal machines, we can provide installation service. Installation and training are free, but our technician’s charges

of freight tickets, hotels and food etc are on your account.