-

ManuThe baler machine works very well.

ManuThe baler machine works very well. -

AnkitYour baler is very good and works well.Scrap metal bales are great.

AnkitYour baler is very good and works well.Scrap metal bales are great.

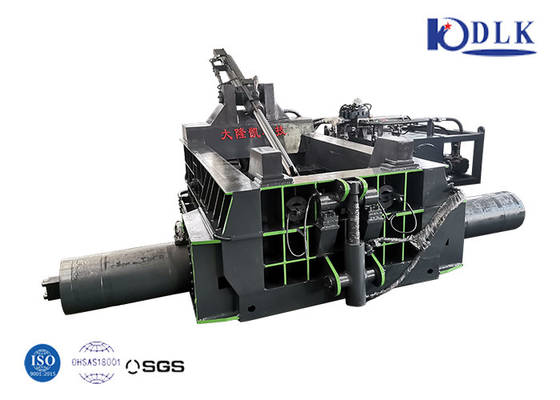

Hydraulic Scrap Steel Baling Press Machine With Automatic Turning Device

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Baling Press Machine | Driven Type | Hydraulic,Electric |

|---|---|---|---|

| Power | 22-60KW | After-sales Service Provided | Overseas Service Center Available |

| Packaging Type | Film | Application | Machinery & Hardware |

| Voltage | Customized | Function | Scrap Metal Baling |

| Productivity | About 7-15 Bags/hour | Outlet Method | Outlet Method |

| Highlight | Scrap Baler Machine With Automatic Turning,Electric Baling Press Machine,Hydraulic Scrap Steel Baling Press |

||

Y81QF-200 Hydraulic Scrap Steel Baling Press Machine With Automatic Turning Device

Product Description

Y81 series balers can be used in scrap metal recycling stations to pack and compress scrap metal scraps. The packaging materials include steel shavings, scrap steel, scrap copper, scrap iron, scrap steel bars, scrap stainless steel, waste oil drums, etc. This fully automatic front-turning baler with a master cylinder pressure of 200 tons is mostly used in small waste recycling stations. The production rate of this baler is approximately 7-15 bales per hour. The bale is 300mm octagonal, and the size of the bale can also be customized if the customer needs. This metal baler can be powered by a diesel engine in places where there is no power supply. In recent years, our hydraulic scrap metal balers have been widely used in the scrap metal recycling industry.

Technical Parameters

| No. | Parameter name and content | |

| 1 | Model | Y81QF-200 |

| 2 | Main Cyl.Force | 2000 KN |

| 3 | Hydraulic system working pressure | ≤26MPa |

| 4 | Tank (compression chamber) specifications | 1800*1400*800 mm |

| 5 | Block section size*minimum length | (600*600)*600 mm |

| 6 | Operation method | Hand-in-one, remote control operation |

| 7 | Productivity | About 7-15 bags/hour |

| 8 | Outlet method | Forward turning-out |

| 9 | Power Specifications | 380 V/3P |

| 10 | Total equipment power | 62.05 KW |

![]()

Application

The horizontal metal scraps baler is suitable for various large, medium and small factories, waste metal recycling processing industry and non-ferrous metal smelting industry.

The used metal baler machine can press various metal scraps, steel shavings, scrap steel, scrap aluminum, scrap copper, etc. into qualified shapes such as cubes, cylinders, octagons, etc. to reduce the transportation and smelting costs of metal scraps materials.

![]()

Company Profile

![]()

Guarantee and after-sale service

1. 12 months guarantee for whole machine

2. 24 hours technical support by email

3. Calling or door to door service

4. User manual and detailed video

Certifications

![]()

FAQ

Q1:Are you a manufacturer, trading company or a third party?

A:We are a professional manufacturer of large and medium-sized hydraulic machinery and equipment in China, and also one of the production bases of metal hydraulic baler and metal shearing machine.

Q2:What is your minimum order quantity, can you send me samples?

A:Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, however,we can send you catalog.

Q3: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Our factory address: 29# Panlongshan Road,Jiangyin city,Jiangsu province,214429, P.R China

Our factory is near Shanghai Pudong Airport.We can pick you up in the airport.

Hotel booking service is available .

Q4:As the shipping period will take long time, how can you make sure the machine won’t be broken?

A:Our machine is film wrapped, to make sure the machine can be delivered to our customer smoothly, we will use the steel wire to fix the machine with the container.

Q5:How to Install ?

A:a.For vertical baler machines, no need to install. This kind of machine is exported by complete unit.

b.For horizontal machines, we can provide installation service. Installation and training are free, but our technician’s charges

of freight tickets, hotels and food etc are on your account.