-

ManuThe baler machine works very well.

ManuThe baler machine works very well. -

AnkitYour baler is very good and works well.Scrap metal bales are great.

AnkitYour baler is very good and works well.Scrap metal bales are great.

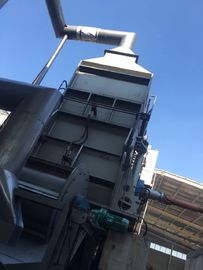

Scrap Metal Shredder Machine Bicycles Empty Cans Recycling ISO9001 Approved

| Automatic Grade | Automatic | Wide Of Feed Opening(mm) | 1200-2500 |

|---|---|---|---|

| Main Motor Power | 160KW-1200KW | Application | Scrap Metal |

| Packaging Detail | In Nude | Blade Length | 1200-2500mm |

| Quality | Grade A | ||

| Highlight | metal recycling shredder,steel scrap shredder machine |

||

380V 3Phase Power , Steel Shredder Machine For Shreddering Scrap Metal

Company Culture

To become the best employees, create high quality products, creat first-class business

Strengthen management, improve service, brand first, quality first

Faith based, innovation, common development

Corporate Mission

We will enter into everyshere in the world.

Make all customers be proud of our products.

Trying to be the leader of our business line.

Applications

The scrap steel shredder is designed to shred a wide variety of light and thin material as discarded automobiles, tin plate, household appliances, bicycles, empty cans, etc, making the materials into pure charge for steel making. By smashing and compressing, the shredder will remove the impurities, raise density, lower transporting and smelting cost to offer good furnace charge for steel plant.

Working Principle

Scrap iron and steel raw materials shipped to feed incline through the scales conveyor, feed incline mounted on two rotatable grinding rollers, high and low , to flatten wins and into the crushing chamber. In the crushing cavity composed of ten fixed on the spindle between the disc and ten security branch of the disc is free to swing the hammer, generated by high-speed rotation speed of scrap metals smashing, torn, broken handle make scrap metal processed into lumps or granules, through the lower part of the grid and the top of the drop in the vibrating conveyor. Firstly it failed to deal with a small enough scrap metal, and will again handle the rotating disc and hammer until it can pass through the grid so far.

Features

1. Equipped with the large inertia, long life, fully enclosed rotating body.

2. Using the heavy duty rotating body bearing.

3. Equipped with good impact resistance of the steel liner.

4. Discharge grille with good to engage in impact performance.

5. The rotating body has lifting device, easy for staff close to the equipment and safety maintenance.

6. Equipped with the hydraulic opening of the upper device and locking mechanisms for maintance staff easy to close to the middle liner to safety repairs.

Technical Specifications:

|

Model |

Wide of feed opening(mm) |

Power(KW/HP) |

Capacity(t/h) |

|

PSX-400/450 |

1200 |

400KW/450KW/535HP |

6-10 |

|

PSX-750 |

2200 |

750(1000) |

15-20 |

|

PSX-900 |

2200 |

900(1200) |

20-30 |

|

PSX-1200 |

2500 |

1200(1600) |

25-40 |

|

PSX-1500 |

2500 |

1500(2000) |

40-50 |

|

PSX-2000 |

2500 |

2000 |

50-60 |

|

PSX-2250 |

2500 |

2250(3000) |

60-80 |

|

PSX-3000 |

2500 |

3000(4000) |

80-100 |

|

PSX-4500 |

2500 |

4500(6000) |

100-160 |

![]()

![]()